Drive intralogistics

evolution with LOJIST

Many companies underestimate the potential of engineering processes to optimize logistics operations. Don’t get left behind.

Seize this opportunity with LOJIST, the WES developed by KFI, which allows your specialists to free up valuable time from daily operations and focus on higher-value strategic activities.

WES and MAO

Platform

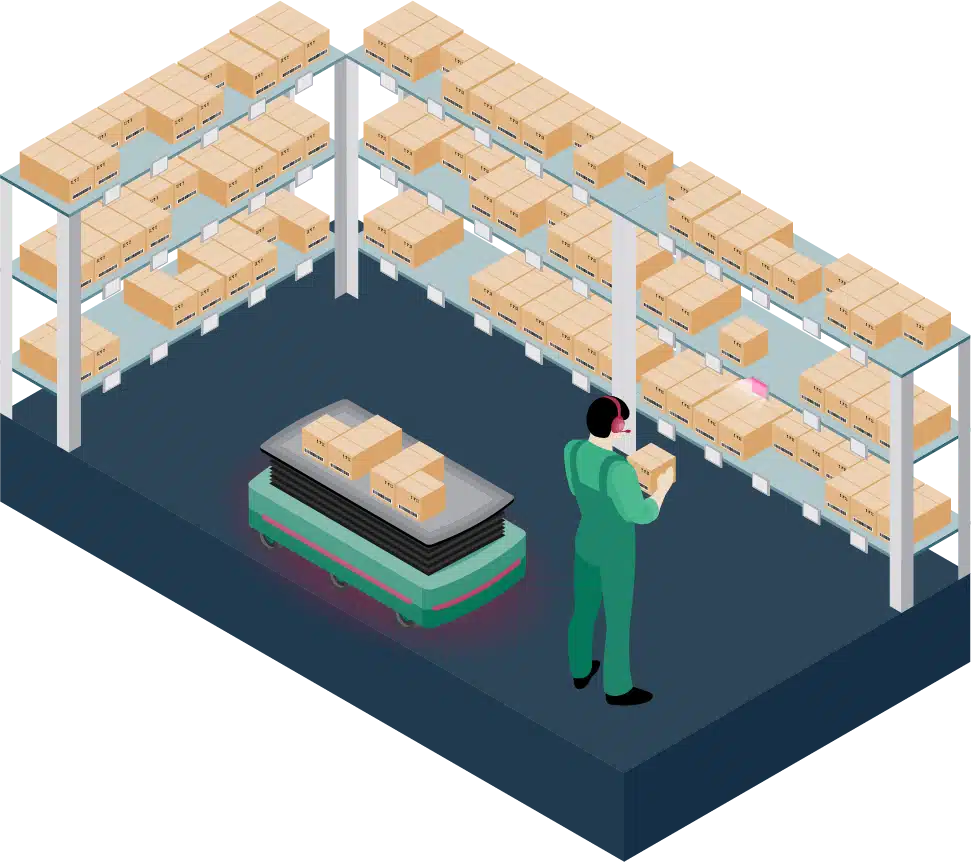

Collaborative

Robotics

Predictive

Work Planning

People and Asset

Tracking

LOJIST redefines the logic of your processes

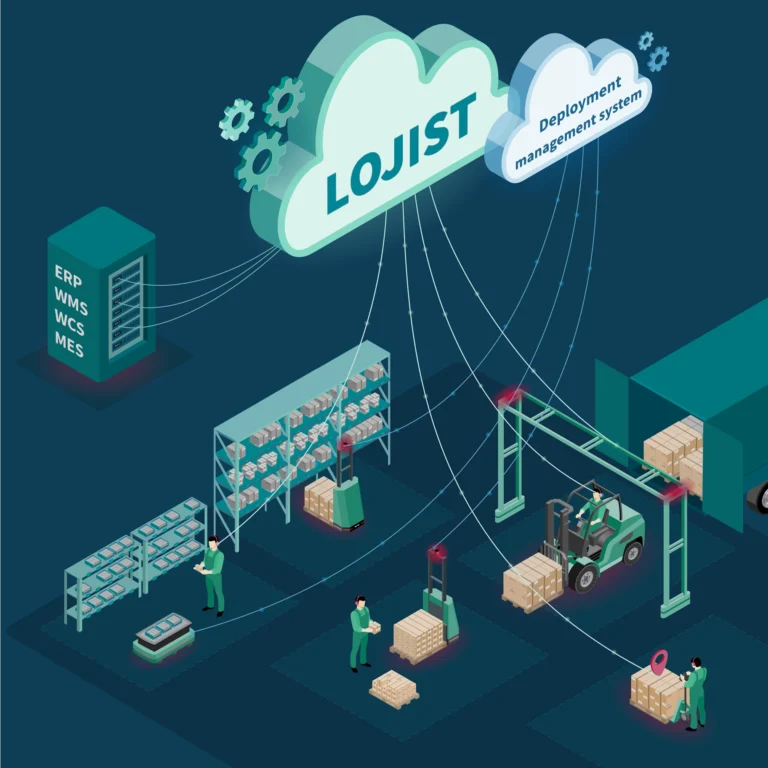

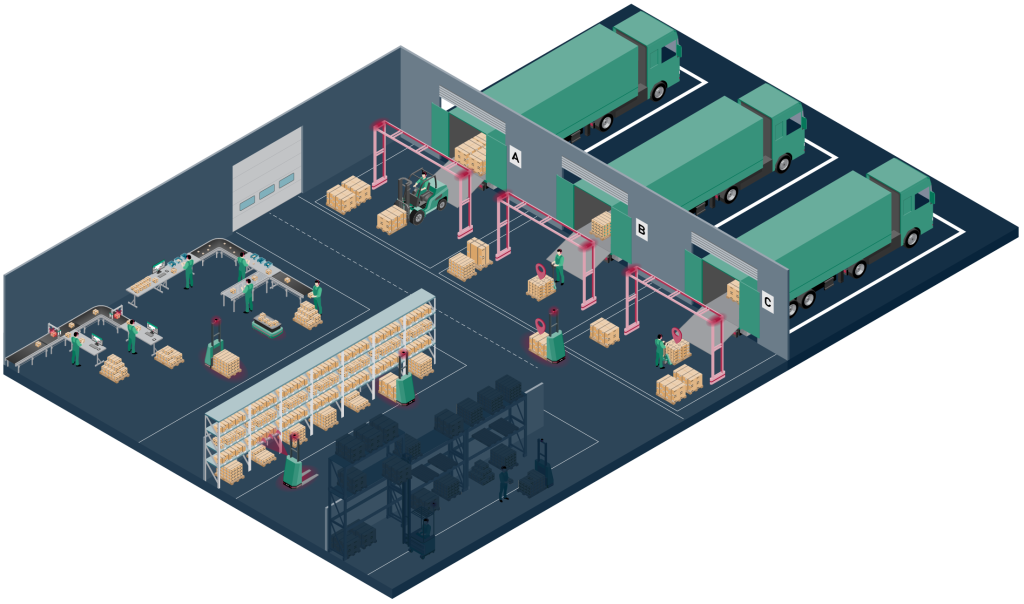

LOJIST is KFI’s modular, multi-technology platform for managing and optimizing intralogistics processes.

It processes data from your information systems (ERP, WMS, MES, WCS) and integrates it with data collected from field technologies to create new, optimized process logics.

Orchestrate your human and technological

resources

LOJIST synchronizes and harmonizes the most advanced warehouse technologies with your information systems.

It configures hybrid solutions by leveraging the advantages of AMR, Voice, Pick-To-Light, RTLS, and RFID to enhance human-machine coordination and revolutionize your processes.

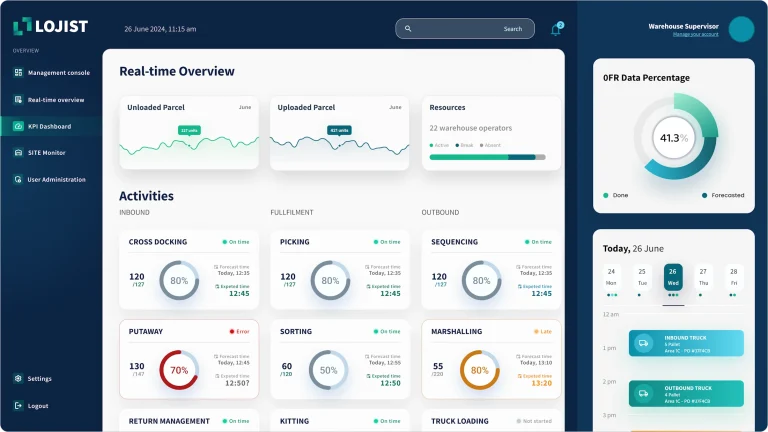

The innovative platform

for your warehouse

DYNAMIC RESOURCE

REALLOCATION

Coordinate order processing timing and location while managing priorities.

REAL-TIME ACTIVITY MONITORING

View the progress of active processes and intervene with corrective actions when needed.

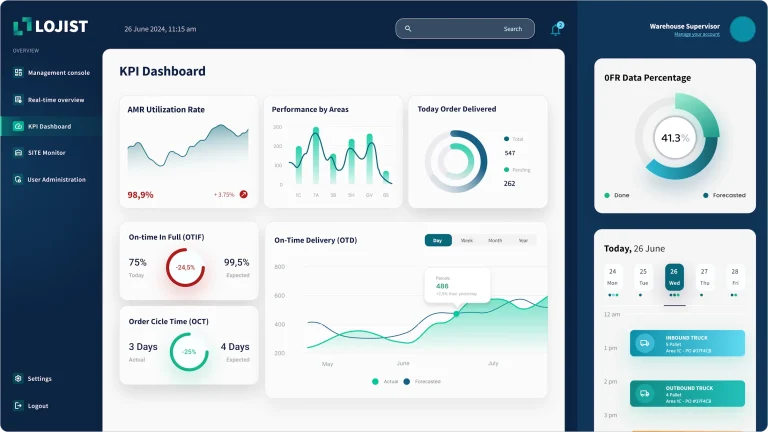

STRATEGIC DATA ANALYSIS

Convert data into structured information and monitor KPIs with customizable dashboards.

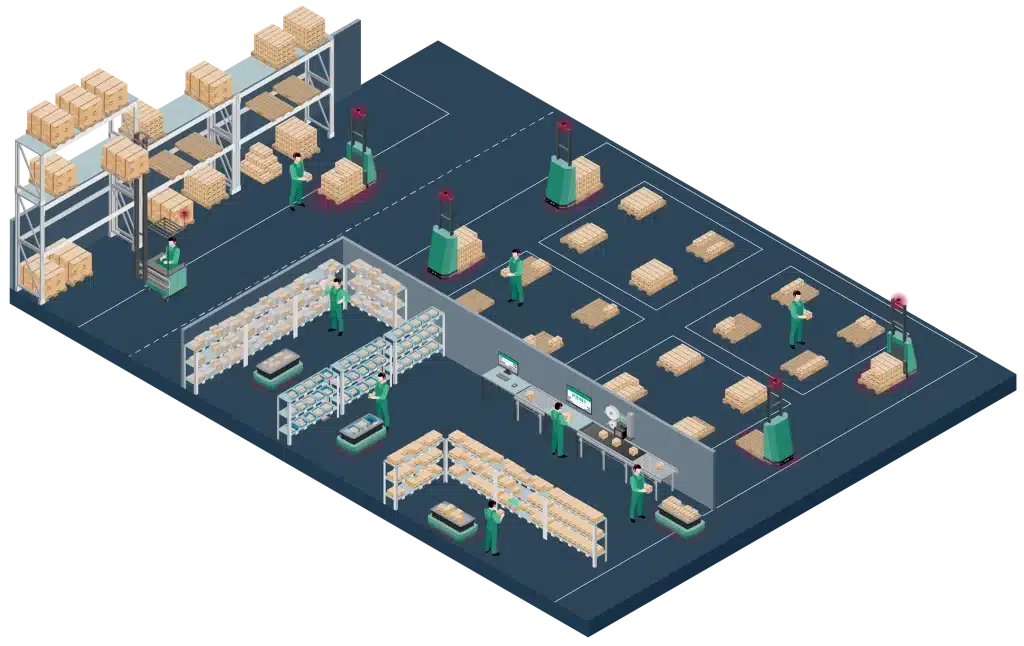

Simplify your order fulfillment processes with LOJIST

Discover how LOJIST’s algorithms make solutions derived from a mix of innovative technologies immediately usable, orchestrating your operators’ activities in synergy.

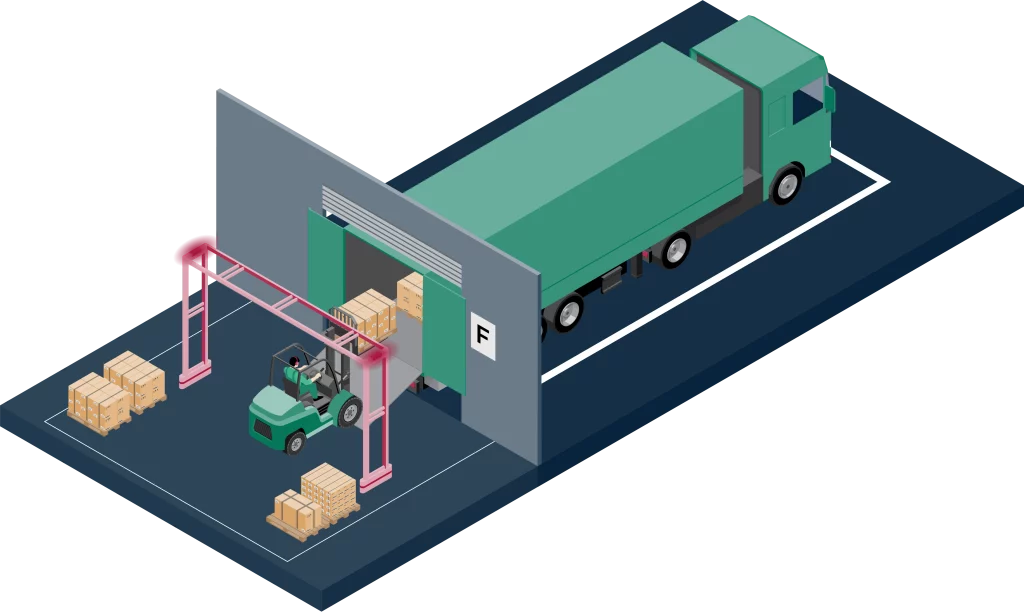

1. RECEIVING

Verify documentation and merchandise compliance to provide a reliable foundation for subsequent intralogistics activities.

2. QUALITY CHECK

Ensure compliance with company quality standards and eliminate data entry activities by integrating inspection data into your information systems in real time

3. RETURN MANAGEMENT

Ensure returned products are classified correctly to recover value and reduce operational costs.

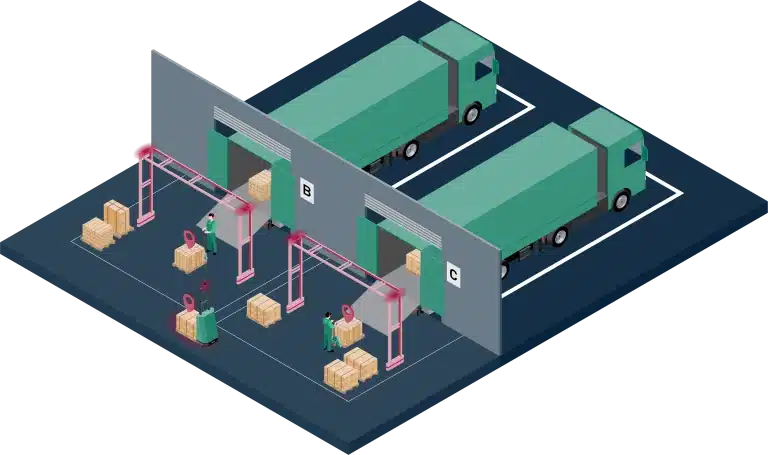

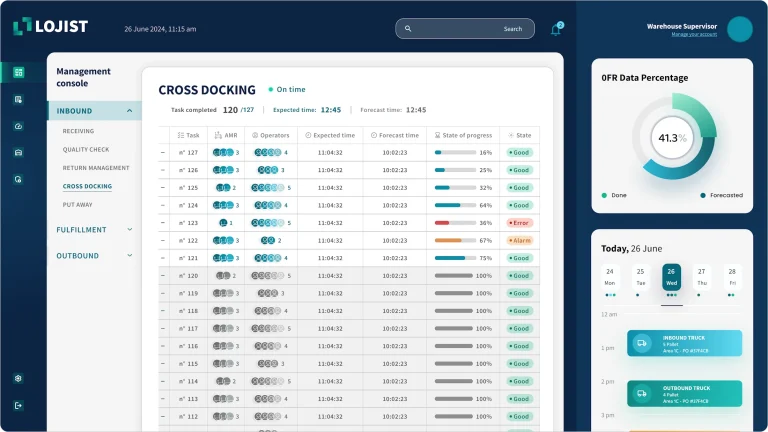

4. CROSS DOCKING

Perfectly synchronize merchandise inflow and outflow, eliminating storage and retrieval time and activities

5. PUT AWAY

Quickly identify optimal storage locations and ensure correct item placement.

6. INVENTORY

Maintain accurate stock control, optimize space and costs, and improve the precision, frequency, and speed of inventory processes.

Inbound

1. Receiving

Verify documentation and merchandise compliance to provide a reliable foundation for subsequent intralogistics activities.

Discover technologies for RECEIVING

2. Quality check

Ensure compliance with company quality standards and eliminate data entry activities by integrating inspection data into your information systems in real time

Discover technologies for QUALITY CHECK

3. Return Management

Ensure returned products are classified correctly to recover value and reduce operational costs.

Discover technologies for RETURN MANAGEMENT

4. Cross docking

5. Put away

Quickly identify optimal storage locations and ensure correct item placement.

Discover technologies for PUT AWAY

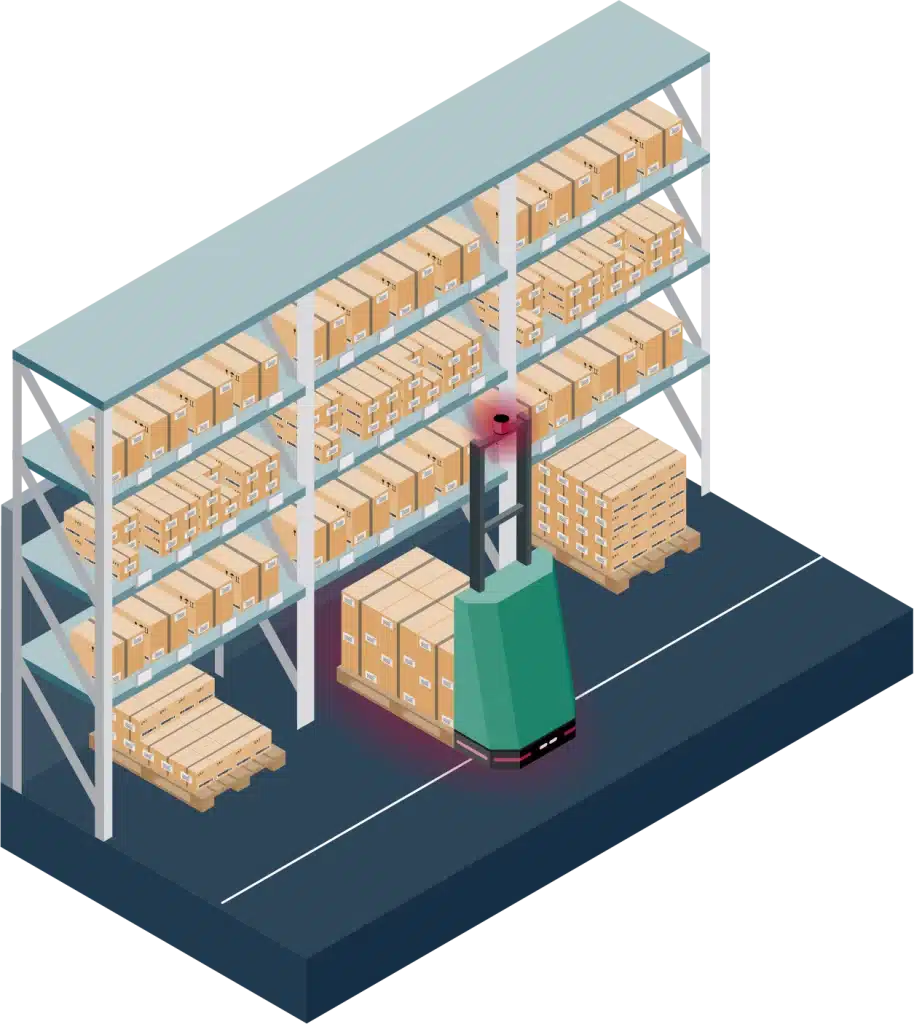

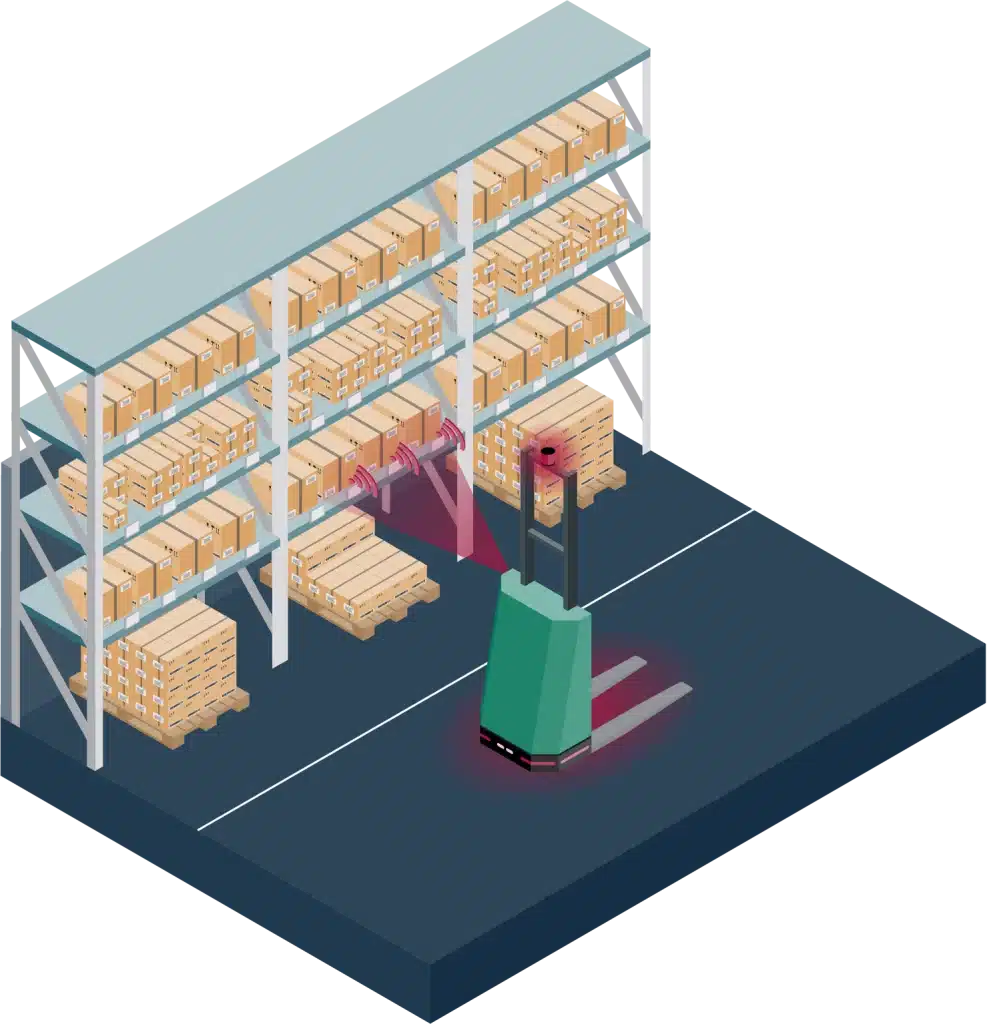

6. Inventory

Maintain accurate stock control, optimize space and costs, and improve the precision, frequency, and speed of inventory processes.

Discover technologies for INVENTORY

Fullfillment

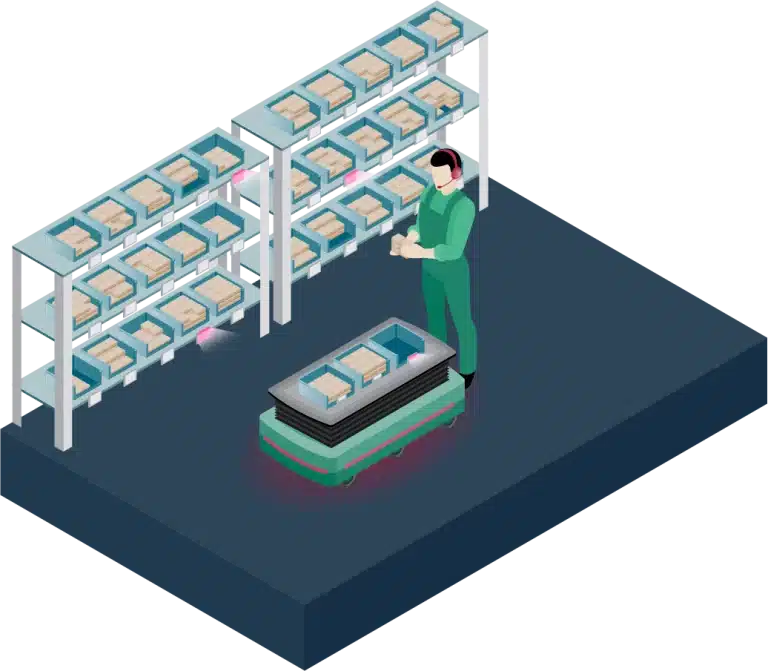

7. PICKING

Quickly locate requested items, intensify activity levels, and minimize errors

Discover technologies for PICKING

8. KITTING

Ensure kits are always complete and accurate to avoid slowing down assembly activities

Discover technologies for KITTING

9. KANBAN & REFILL

Replenish stock just-in-time, restocking as it is consumed to ensure necessary materials are always available

Discover technologies for KANBAN & REFILL

10. REPLENISHMENT

11. SORTING E-COMMERCE

Sort and place picked items into subsets destined for different routes, ensuring each customer receives their online order immediately

Discover technologies for SORTING E-COMMERCE

12. SORTING FRESH GOODS

Sort and place fresh products like fruits and vegetables into subsets for different routes, ensuring proper preparation of packages for retailers.

Discover technologies for SORTING FRESH GOODS

13. PACKING & CONSOLIDATION

Accelerate parcel packing with information on dimensions, materials, labels, and DDT for efficient shipping.

Discover technologies for PACKAGING & CONSOLIDATION

7. PICKING

Quickly locate requested items, intensify activity levels, and minimize errors

8. KITTING

Ensure kits are always complete and accurate to avoid slowing down assembly activities

9. KANBAN & REFILL

Replenish stock just-in-time, restocking as it is consumed to ensure necessary materials are always available

10. REPLENISHMENT

Replenish stock to ensure products are always available for sale or production and easily accessible to pickers.

11. SORTING E-COMMERCE

Sort and place picked items into subsets destined for different routes, ensuring each customer receives their online order immediately

12. SORTING FRESH GOODS

Sort and place fresh products like fruits and vegetables into subsets for different routes, ensuring proper preparation of packages for retailers.

13. PACKING & CONSOLIDATION

Accelerate parcel packing with information on dimensions, materials, labels, and DDT for efficient shipping.

14. SEQUENCING

Organize goods and components in the required sequence to improve production line and warehouse efficiency.

15. MARSHALLING

Ensure fast and safe transfers of goods, reducing operator movements, waiting times, and handling errors.

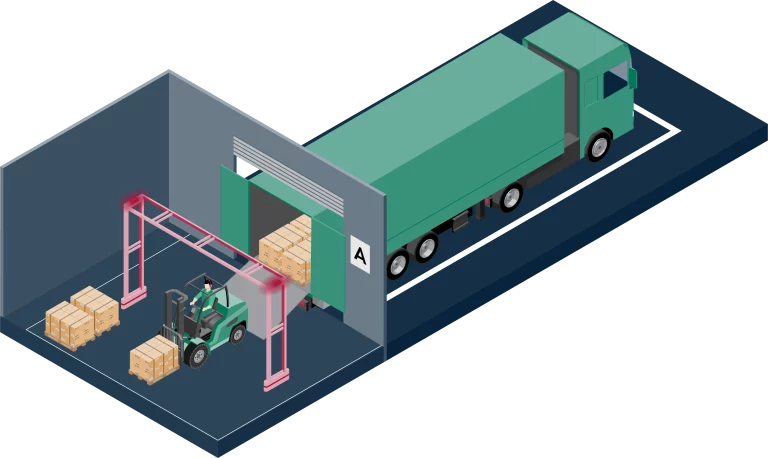

16. TRUCK LOADING

Reduce loading and unloading times, optimize space usage, and photographically certify the load to avoid disputes.

Outbound

14. SEQUENCING

Organize goods and components in the required sequence to improve production line and warehouse efficiency.

Discover technologies for SEQUENCING

15. MARSHALLING

16. TRUCK LOADING

Reduce loading and unloading times, optimize space usage, and photographically certify the load to avoid disputes.

Discover technologies for TRUCK LOADING

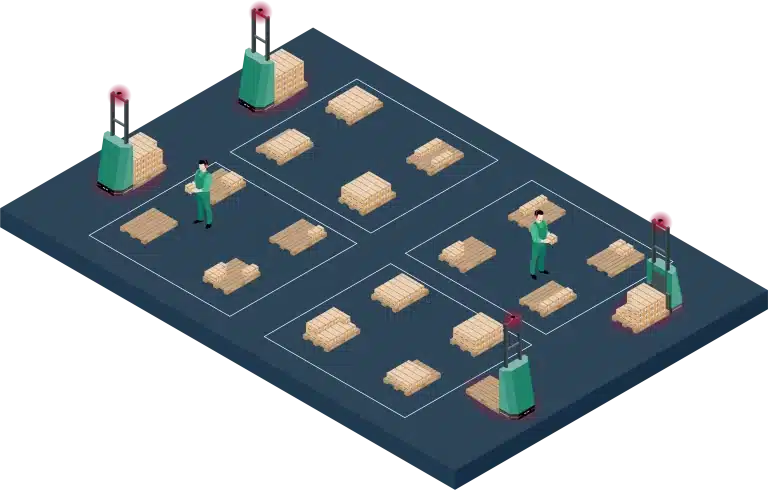

LOJIST introduces Hybrid

Workforce Management

to your warehouse

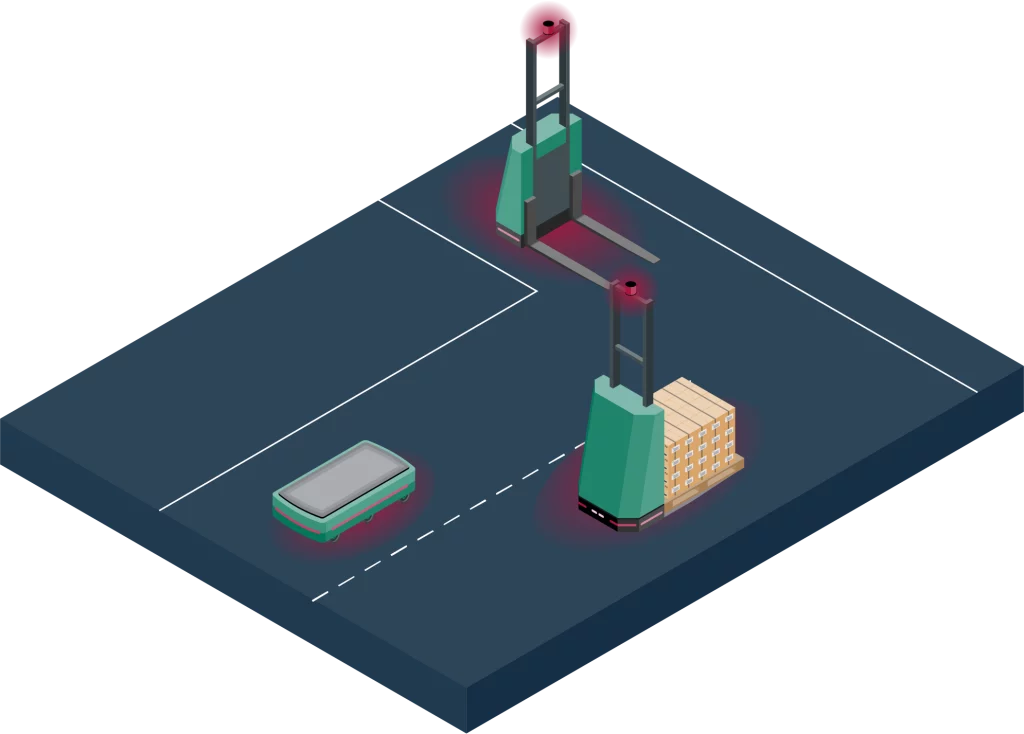

Collaboration between humans and robotics (AMR) is the winning key to tackling the labor shortage challenge.

Control costs and lighten employee workloads while reducing the impact of turnover on your operations.

Choosing LOJIST means choosing

process optimization

Compatibility and integration with any WMS and WCS

Redefinition of workflow logic

Dynamic reallocation of operational resources

Real-time management of high-priority orders

Agnostic technology orchestration

Balancing of various automated areas

Human-Centered workflow automation

Human-machine coordination in HWM mode

LOJIST helps businesses improve

the efficiency of distribution processes

Configure the solution that

best suits your needs

Combine LOJIST’s modules to create a customized and scalable platform, including only the technologies and logic most suited to supporting your company’s growth and processes.