Bright solutions for fast, efficient picking

Pick/Put-to-Light technology leverages a system of LED lights to improve productivity in picking and sorting operations. It eliminates paper, drastically reduces errors, increases productivity, and boosts operator satisfaction.

Why Companies Choose an

Advanced Picking System

REDUCED ERRORS

Misplaced items

Quantity errors

Mistaken picking of similar codes

INCREASED SPEED

Enhanced human-machine interaction

Reduced inefficiencies

Simplified location identification

PAPERLESS PROCESSING

Digitalized workflows for greater sustainability Real-time, structured, and up-to-date information

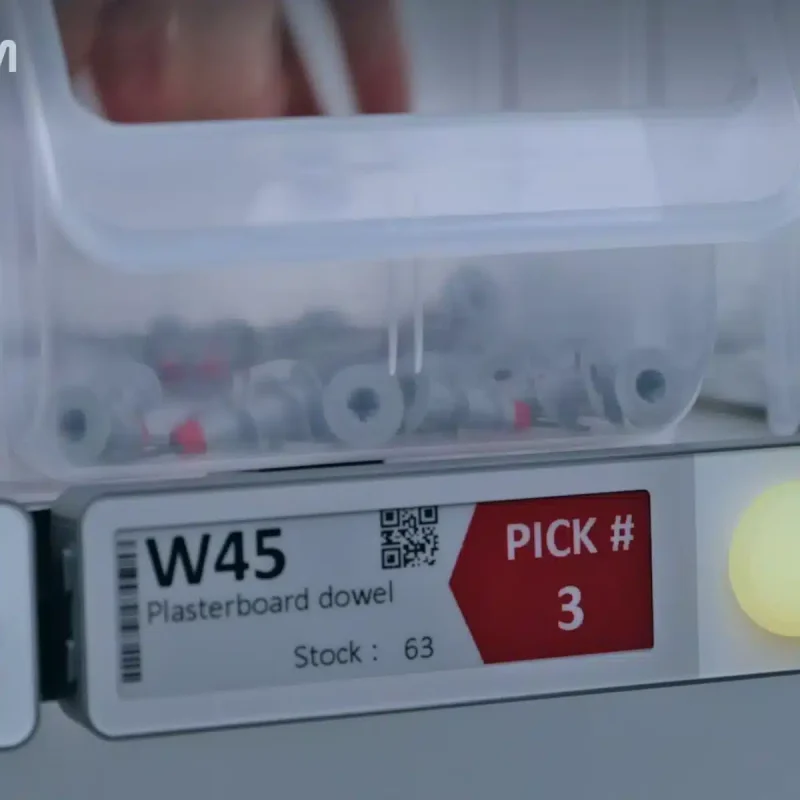

Electronic shelf labels (ESL)

Electronic shelf labels enable paperless management of industrial processes, improving precision and productivity. Durable and fast, they simplify operational activities such as picking (Pick-to-Light) and placing (Put-to-Light).

Battery-powered with customizable displays, ESLs are versatile and adaptable to the evolving needs of company intralogistics.

Discover electronic shelf labels

BENEFITS

Reordering items directly from shelves

Digital cards for internal transport

Easy product identification

Transparent equipment and machinery management

Optimized picking operations

Digital visualization of tasks

CGT

CGT revolutionizes its spare parts picking process with Vocalize® and wireless Pick-to-Light solutions

MANAGED PROCESSES

1. Picking

LED lights guide operators to locations, making it easy to identify items and confirm picks with a simple touch.

2. Kitting

Light-guided picking and sorting ensure kits are complete and accurate, avoiding delays in assembly tasks.

3. Kanban

With a single button press on the ESL, operators can promptly request material replenishment, preventing stockouts.

4. Sorting

Bright indicators clearly show where products should be placed, minimizing location errors.

5. Return Management

LED guidance speeds up the sorting of returns to their correct destinations, reducing errors.

6. Inventory

Pick/Put-to-Light solutions connected to the centralized management system allow for real-time inventory updates.

Governs data from enabling technologies with LOJIST, for creating optimized process logic

Software applications are indispensable for process optimization and effective management of data collected from field technologies

LOJIST: The WES to drive intralogistics evolution

LOJIST is an innovative software that facilitates the integration of automated systems and robotics into manual processes, optimizing Order Fulfillment performance.

Orchestrates workflows for current and incoming orders

Harmonizes human-machine coordination

Provides real-time visibility and balances resources

Regulates the workload assigned to various technological subsystems (AMR, Voice, Pick-To-Light, RTLS, RFID)

Maximizes overall throughput