Client company:

CDU Consorzio Distributori Utensili is a consortium association made up of 25 of the best national companies in the tool and hardware sector.

Solution Scope:

implementation of the Vocalize voice solution for the optimization of the warehouse picking process

The challenge

A logistical process to be tailored

The expansion of the Consortium has gradually led to the creation of a centralised warehouse for the management of external brands as well as proprietary brands, such as TKN. From this platform, CDU supplies the associates’ points of sale daily and, lately, the final customer as well. At the same time, in a short time, the managed references went from around 1,200 to over 4,000.

“These evolutions have led to an increase in logistical pressure, further emphasised by health emergency” comments Aldo Basile, the General Manager of CDU. “We began to feel the need to make the picking process more efficient and, at the same time, to significantly reduce time and error percentage”.

The entire process was in fact managed through paper supports and was based on the memory of the operators. This generated quantity and substitution errors, especially since workers are often called upon to handle very small and similar items. This resulted in complaints, the handling of which resulted in further activities that slowed down operations and entailed additional costs.

The solution

The voice which guides memory

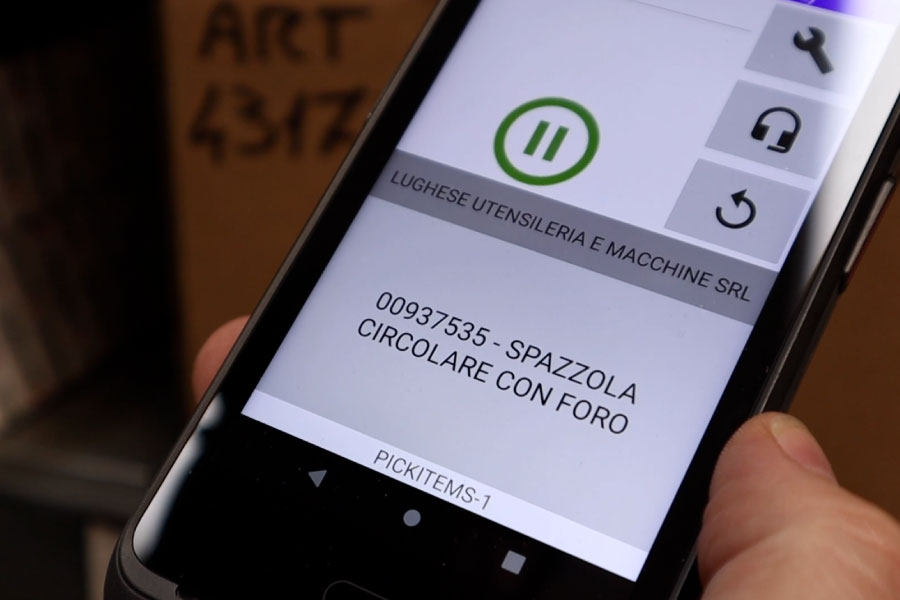

KFI intervened by introducing the Vocalize solution in the CDU warehouse, a voice guidance system, in this case used to support picking activities.

“We opted for voice because, as we often have to handle medium-sized objects, we wanted the operators to have their hands free. The choice fell on Vocalize because this solution allows for much more: a uniform and optimised picking cycle, accompanied by an error reduction of over 60%. Furthermore, Vocalize is a native Android application, an open system in which other business partners can intervene to allow us to obtain a growing integration of other company systems”, Basile comments.

The warehouse was in fact labelled by assigning codes to the locations, which were then registered on the customer’s management system, associating their respective contents.

Thanks to a discussion with the supplier of the WMS system, it was possible to automate the picking lists sending procedure, which now appear on the Vocalize dashboard displayed on the monitor of a fixed station.

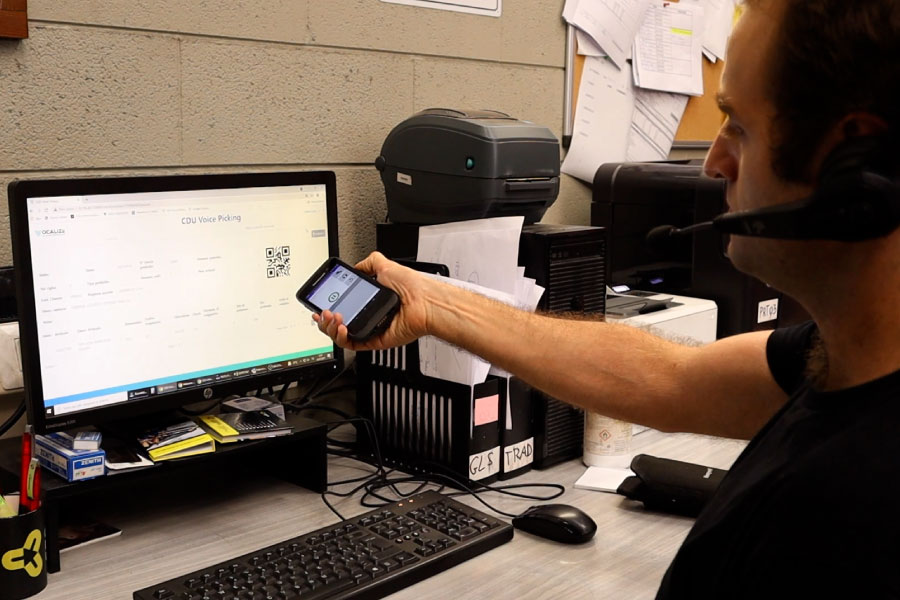

All the operator has to do is go to the general desktop computer and acquire, by means of a scanner, the order identification QR code on the screen. At this point Vocalize uploads the information relating to the selected picking list onto the workers’ PDA and guides them through activities. This way, it is possible to directly access the picking lists through the dashboard, without going through the WMS.

The results

Not just picking: route optimisation

In this case, the KFI software compensates also for a weakness of the pre-installed WMS, namely the lack of a feature aimed at optimising the picker’s route. Thanks to Vocalize, the operator picks up all the items in the list following the shortest path. Arriving at their destination, confirms being in the right place by reading the location code and receives via the headset the quantity to be picked, thus minimizing the possibility of making mistakes.

According to Basile “Initially the operators were sceptical about the voice solution. However, after testing it, they realised that they travel much less and are less tired at the end of their shift. This has allowed them to better face even the work peaks associated with the first days of the month, so much so that now they are able to close the shift as in normal periods. In fact, we have achieved an approx. 15-20% increase in productivity. Currently, operators are so used to following the voice guiding them that, if they were to start making pickings in an analogue way, they would probably take greater pains”.

After picking, if the order does not include items stored in the automated warehouse (for which a different picking procedure is provided, based on indications provided by lights and displays), Vocalize directly issues the shipping bill. This is then taken, together with the picked items, to the consolidation station, where an employee takes care of packing and sending the goods.

The satisfaction of CDU

An innovative mentality, a kept promise

“It is the first time I have seen a Gantt respected with such precision, it had never happened to me. KFI has met all deadlines and I am aware of how difficult this is when it comes to software”, adds Basile satisfied. Furthermore, according to the General Manager, “KFI has not only introduced technology, but also an innovative mentality that has brought additional value in the organisation of work and CDU growth”.

It is therefore not surprising that CDU and KFI are already working on the next steps. The management through Vocalize of the goods receipt and the photographic certification of the material sent to the end customer will in fact allow the consortium to close the logistic optimisation circle.

Aldo Basile, after many years of experience in Würth that allowed him to specialise in the topics of Lean Production in the United States, he has held the post of General Manager CDU since 2020.