Introduction

La Doria has recently adopted RFID technology and KFI automated applicators to enhance its products’ traceability and improve system integration in order to support production, logistics, quality and maintenance processes.

La Doria Group

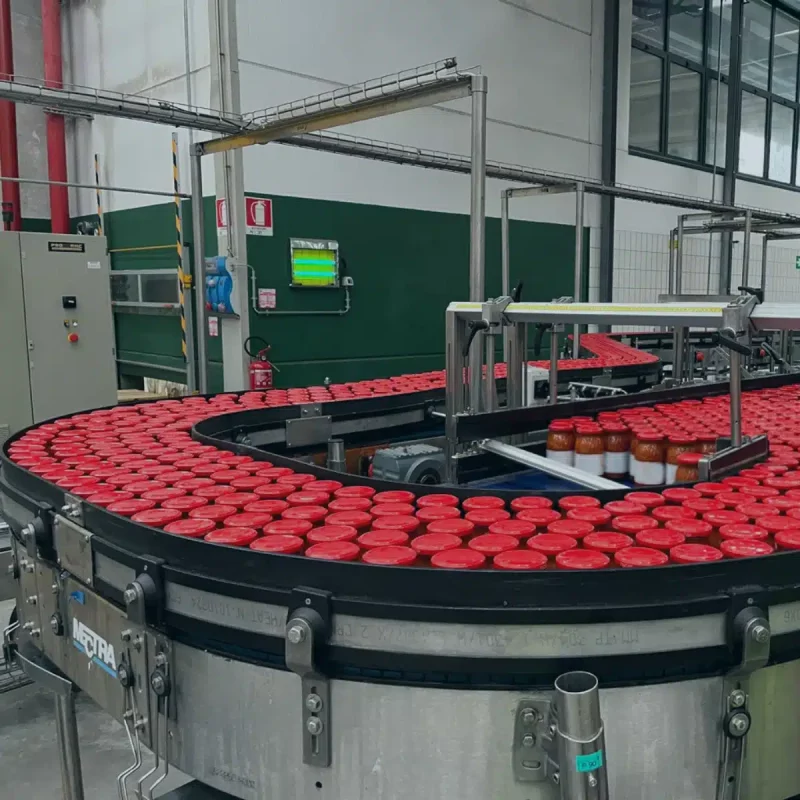

La Doria finds itself rooted in Southern Italy, deep in the Nocerino-Sarnese countryside; this area was initially devoted to tomato cultivation and, over time, became one of the two Italian epicenters of the processing of this product.

Founded as a family business in the 1950s, La Doria specialized in tomato processing; today, it is a renowned food company and an international leader in the canning industry.

Customer

Objectives

Higher control within merchandise identification

Providing a basis for improved product traceability

Promote digitization, improve safety, increase speed and reduce errors in processes

Achieved Results

Considerable reduction of product shipment errors

Increased productivity

Seamless integration of Hardware and

Software within business processes

The challenge

Digital transformation supports seamless product identification

Implementing RFID technology at La Doria’s production sites is part of a larger project aimed at adopting innovative technological solutions to promote digitization, improve safety, increase speed and reduce errors within production and logistics processes.

During this initial phase, the company aimed to lay down the foundations to improve the traceability of its food product, starting with solving a particularity that would arise during the pallet packaging process.

Here, the packages were directed to the wrapping machine, where the identification label was removed and then reapplied after placing the stretch film needed to stabilize the load.

Errors resulting from this operational sequence prompted the company to implement a higher level of control to signal increased attention to customers and to ensure they received the correct products.

The solution

Integrated technology enhances traceability

Further down the production process, when the production lines separate, La Doria installed three advanced automatic KFI applicators (AP 150 – AP 190) that place RFID labels containing key information on palletized products. The RFID label adds a radio identification element to the traditional bar code, substantially contributing to the overall improvement of traceability.

In fact, during this process, the pallet with the RFID label moves towards the wrapping machine where the system reads the data stored in the chip through an antenna. A label is then processed and printed with all the relevant information and is ready to be applied once the package has been prepared.

As a result, the introduction of RFID technology has led to a complete revision of the process, involving not only applicators but also scanners. Additionally, this system, which is crucial in the smart factory project, will also be the basis for future advancements in packaging, shipping, and storing, including integration with the process logic of automated warehouses in the plants.

LOJIST

Through its WES platform, KFI excels in integrating Pick-to-Light technologies into business processes and systems for item picking and sorting.

Acting as an interface with ERP, WMS, MES, and other management systems, LOJIST provides centralized access to data from order fulfillment solutions, streamlining business process orchestration.

The results

Collaboration is the key for success within the pathway of innovation

RFID technology has revolutionized how products destined for warehouses and customer deliveries are identified and managed. As a result of this innovation, shipment errors have been almost completely eliminated whilst simultaneously enabling a significant increase in operational efficiency.

Addressing change in the manufacturing and logistics areas has been a challenge. Still, recognizing that managing the opportunities presented by digital transformation requires skill and governance, users have enthusiastically embraced the new technological philosophy. These advances have enabled La Doria to advance toward Industry 5.0 by harmoniously combining advanced technical solutions and human skills.

Thus, the success of this project was determined not only by the correct selection of software and hardware solutions to support processes but, more importantly, by their synergistic integration. KFI played a key role as a technology provider and, more importantly, as a guide in introducing such solutions into business processes.

“In the context of corporate businesses, the IT department emerges as strategic, making a major contribution to cost management and revenue growth through efficient integration of processes, systems and human resources. Internal IT emerges as an enabler of innovation, but choosing the right partner is critical for success.

Deep collaboration among the departments and people involved makes all the difference in this continuous innovation journey. KFI, realizing that merely providing hardware is no longer sufficient, has committed to supporting La Doria in process optimization, recognizing the importance of offering systems assistance to support activities, as well as advice on how to apply it.”

Raffaele Todisco, CIO of La Doria